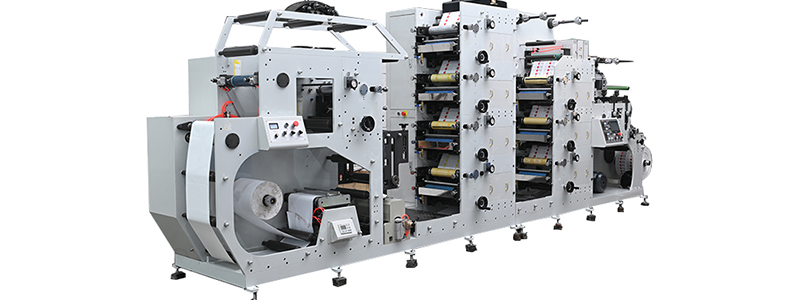

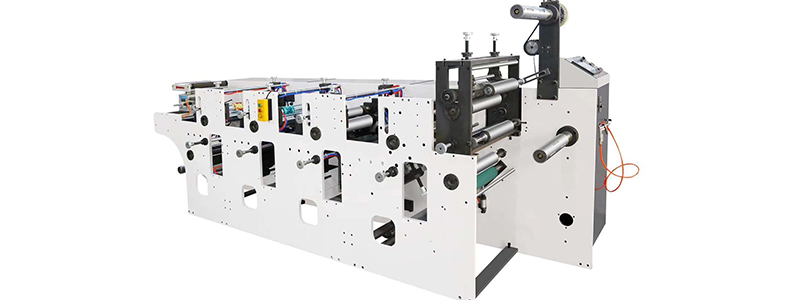

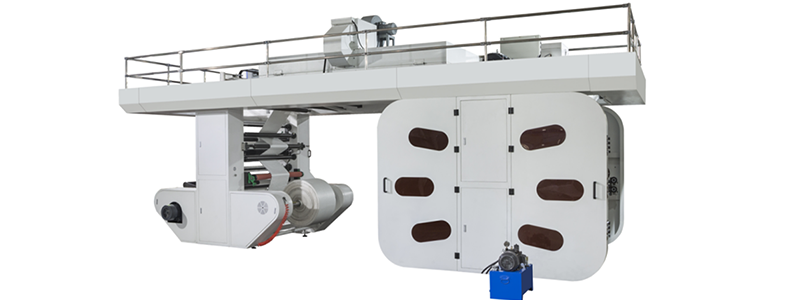

YB-450-P10 Servo type automatic Flexo Printing Machine

High speed flexo printing machine speed 150m/min,Max printing width450mm,The control system adopts Japan yaskawa's latest servo control system ,Each unit is driven by a servo motor,The whole machine adopts 12 servo motors(10 colors),Provide guarantee for high precision alignment in high speed running of the machine,The plate roller is installed by pillow, made of aluminum alloy, with high precision helical gear transmission, easy and fast operation.

Main Technicial Parameter :

Max. printing speed: 150m/min

Max . ponting width: 450 mm

Max. Width: 460 mm

Max .unwind diameter: 1050 mm

Max. exhaust diameter: 900 mm

Max. repeat length: 254-609.6 mm

Loading method: drum-type

Horizontal overprint adjustment: By hand

Longitudinal overprint control: 360°servo drive

Preliminary overprint: automatic

Fast changing ink system: Quick change of ink tank

Lubrication way: automatic

Division is introduced :

1. Unwinder parts 1set

♦ Unwinder Max diameter Ф1050mm , Pneumatic feeding

♦ Ф3” air shaft

♦ Magnetic powder drum tension control system

♦ Pneumatic paper clipping platform

♦ BSTA utomatic EPC drive

♦ Pneumatic components adopt AirTAC

• Corona device effectively increases the amount of ink on film

• Remove electrostatic device from material surface

• high speed flexo printing machine Remove dust from raw material surface with dust removal device

2. UV drying system

• Using the performance of frequency conversion power supply, the same output power is 30% less energy saving than the common lighting device

• Power has manual and automatic two options, manual stepless control power;Automatic power changes with the speed of the printing machine and automatically follow the change, and can individually fine-tune the color group of power.

Compact size and convenient installation

Drawer - type structure is adopted to facilitate paper - passing and maintenance

3. Waste collection reel unit

• Full servo PID automatic operation mode, with the coil size increase power automatically increase

♦ Ф 3 "gas rose axis, with revolving air connection

• Maximum scavenging diameter: 900mm

Electric control charging/deflating device for air surge shaft

4. Rewinding device

♦ winding Ф 1050 mm in diameter

Pneumatic feeding mode

♦ Ф 3 "gas rose axis

• Variable frequency motor can adjust the output torque according to the winding diameter to ensure the stability of the winding tension

5. BST online color quality monitoring system

• AOC 22 "color display

Contactor gear sensor

• Can easily adjust the focal length, magnification, image contrast and so on

• high speed flexo printing machine A variety of monitoring mode selection, tracking, monitoring printing efficiency, etc

Pictures are for reference :

After-sales Service

1.One Year Warranty,As long as there is a non-human fault in a year,free re-placement parts.

2.Parts Replacement,Don’t worry about the parts damaged or not sold after the machine is sold.we have a field factory with hundreds of enployees to serve you.

3.Engineer Asssignment,Lifelong maintentance,If your equipment breaks down,we will arrange engineers to repair it.

4.Online Instruction,We open online services,as long as your equipment failure,our engineers will be the first time for a one-to-one trou-bleshooting.

5.Feedback Survey,The engineer is required to bring a questionnaire to fill in the satisfaction with the engineer and the use of the equipment.